Cryogenic Liquid Nitrogen Oxygen Argon LPG ISO Tank Container

Cryogenic Liquid Nitrogen Oxygen Argon LPG ISO Tank Container Product Function for 20feet T75/T50 LNG/CNG ISO Storage Ta

Basic Info

| Model NO. | JSX2023LPG for Gas Container |

| Experice | >10 Years |

| Producing Period | >20 Days |

| Frame Size | 20ft |

| Life Span | >25 Years |

| Color | Customized |

| Loading Capacity | 25000L |

| Maximum Gross Weight | 35000 Kg |

| Tare | 6800 Kg |

| Design Temperature(ºC) | 55 |

| Operating Temperature(ºC) | -40~50 |

| Filling Medium | 1, 2-Tetrafluoroethane |

| Tank Instruction | T50 |

| Max. Payload (Kg) | 22568 |

| Hydro.Test Pressure(MPa) | 2.18 |

| Leakage Test Pressure(MPa) | 1.38 |

| Transport Package | by Container Vessel for This Tanker Container |

| Specification | 12460*2500*3980/mm carbon steel tanker |

| Trademark | JUSHIXIN |

| Origin | Mainland of China |

| HS Code | 8609001200 |

| Production Capacity | 200units/Month for ISO Storage Tank Container |

Product Description

Cryogenic Liquid Nitrogen Oxygen Argon LPG ISO Tank ContainerProduct Function for 20feet T75/T50 LNG/CNG ISO Storage Tank Container

***This series tank semi trailers are suitable for the transportation 1,1,1,2-Tetrafluoroethane,LNG,LPG,Etc. Gas.*** The volume is under 25 cube meters, we can manufacture it according to your needs.

Product Details for 20feet T75/T50 LNG/CNG ISO Storage Tank Container.

1).The related Specification for this container tanker:

| Dimension of the 20FT 20CBM T75 Liquified N2 Tank Container with Lloyd's CSC Certificates | ||||||

| Description and Specification of Commodity | ||||||

| Codes and regulations | IMDG-CODE. GB150-98 ASMI-VIII-1 JB/T4781-2005 | |||||

| UN code. | 1977 | |||||

| Design Standards | CCS, Basis: IMDG. CSC. TIR. UIC. RID | |||||

| Approval and inspection org | Lloyd's Register(EN standard) | |||||

| Tank Shape | 20FT | |||||

| Tank Shape | Column Shape,Horizontal | |||||

| Nominal Medium | 20500L | |||||

| Loading Medium | LNG,LCO2,LN2,LO2,LAR,LN2O,LC2H4 | |||||

| Gross mass(kg) | 34000 | |||||

| Tare Weight(kg) | 11050kg | |||||

| Payload(kg) | 22000kg | |||||

| Maximum Gross Weight | 34000 KG | |||||

| Tolerances: | on volume 1%,on weight 2% | |||||

| Stacking | 192000kgs | |||||

| Tare | 7750 KG(Maximum tolerance 3%) | |||||

| Filling ratio | 95% / 85% | |||||

| Max. Allowed Working Pressure | 16Bar | |||||

| Design Pressure | 22Bar | |||||

| Test Pressure | 20Bar (Hydraulic Pressure test) | |||||

| Corrosion Degree | 0 | |||||

| Max. Outside Pressure(Mpa.) | 0.1 | |||||

| Baffles of the inner vessel | Two transvers baffles | |||||

| Surface treatment of the inner vessel | Pickling | |||||

| Material of the inner vessel | Stainless Steel | |||||

| Material of the out jacket&Frame | Low alloy steel | |||||

| Surface treatment of the out jacket | Shot blast SA2-1/2" | |||||

| Outer Vessel | ||||||

| Design Temperature(°C) of the out jacket | -20 to 50 | |||||

| Design pressure | -1 barg(full vacuum) | |||||

| Outer Diameter | 2420mm(not protruding over the frame members) | |||||

| Overall length | 6000mm(not protruding over the frame members) | |||||

| Vacuum Test Pressure(Mpa) | 0.1 | |||||

| External Tank thickness(mm) | 6 | |||||

| Inner Vessel | ||||||

| Max. Allowed working pressure | 16bar | |||||

| Pressure vessel code | AD2000-Regelwerk | |||||

| Test and calculation pressure | 20bar | |||||

| Design temperature(ºC) | -196 to 50 | |||||

| Working Temperature(ºC) | -196 to 50 | |||||

| Outer Diameter | 2200mm | |||||

| Inner Tank thickness(mm) | 16 | |||||

| Number of baffles | 2 | |||||

| Corrosion Degree | 0 | |||||

| Gastight Test Pressure | 14.4Bar | |||||

| Type of insulation | High vacuum multi-layer | |||||

| Static evaporation rate | Ln2 0.35%/d | |||||

| Welding Joint Efficiency | 1 | |||||

| Radiographic Inspection | 100%X-RAY | |||||

| Vacuum | ≤0.1pa(Warm) | |||||

| Net evaporation rate | ≤0.33%/d (Ln²)(ambient condition:100kpa and 15°C | |||||

| Inner End Enclosure(mm) | 18 | |||||

| External End Enclose(mm) | 8 | |||||

| Piping material | Stainless Steel type 340(L) | |||||

| Valve types for cryogenic tanks | cryogenic valves | |||||

| Safety Valve | DN25 PN2.5 DAH-25A1 | |||||

| Vaporator | DN25 | |||||

| Hose and Hose box | YES | |||||

| Top inlet pipe | DN40 | |||||

| Bottom inlet/outlet pipe | DN40 | |||||

| Reflux tube | DN40 | |||||

| Liquid level gas phase tube | DN10 | |||||

| Liquid level liquid phase tube | DN10 | |||||

| Monitoring tube | DN10 | |||||

| Threaded connection for drain and fill pipes | NIT-150 | |||||

| Valve box | 1 | |||||

| Guardrail of Ladder(mm) | W=400 | |||||

| Allowable stacking weight | 192000 | |||||

| PBC | 120NM³ | |||||

| DP gauge | 6 inch dial(Range:0~4000mmH2O) | |||||

| Pressure gauge | DV-6R Thermocouple probe | |||||

| Inner tank material: | SA-240 ASME Certification | |||||

| Outer vessel: | SA-516M ASME Certification | |||||

| Overall Size(Frame)/L*W*H/mm | 6058*2438*2591 | |||||

| ISO-cornercastings | 20'x8'x8'6" ISO dimensions | |||||

| Frame | ||||||

| The frame is of "Beam Type",consisting 8'X8'6"-frame at each end,connected to each end.Handling to be done by means of the corner castings only.The container can be secured by twist locks on rail and road vehicles complying to the relevant requirements of ISO668 Freight containers. | ||||||

| Insulation or Sun Shield | Sun Shield | |||||

| Paint | Frame | 30µm +40µm +50µm | ||||

| Shell | 30µm +40µm +50µm | |||||

| Thermal Treatment(YES/NO) | YES | |||||

| TANK INSTRUCTION | T75 | |||||

| Dossier | Two copies of tank dossier in English & Chinese, | |||||

| Manuals | Two copies of operating manual in English & Chinese | |||||

2) Some photos for our Tank Container Workshop:

>>>Certificates for the Gas Container

3) Detailed photos for the Gas Tank Container:

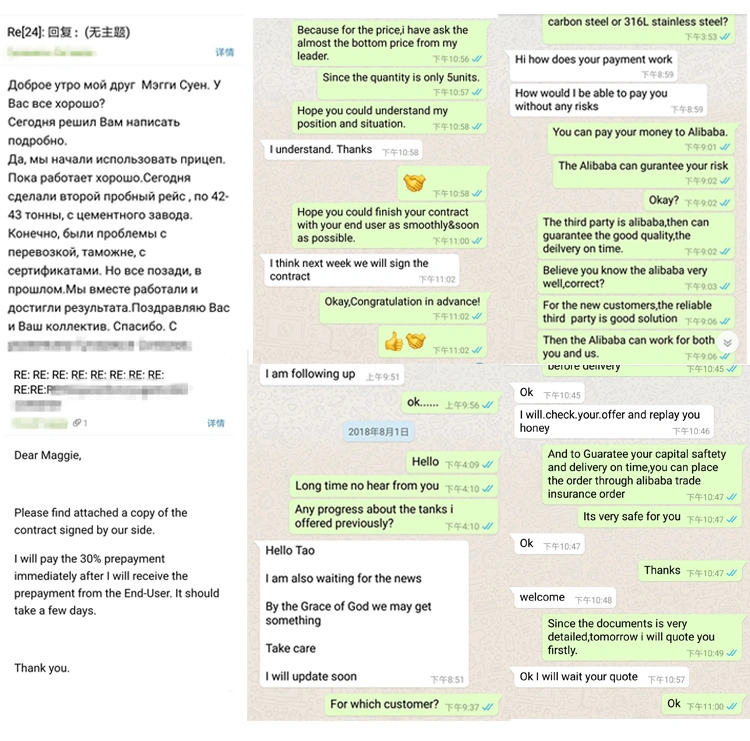

4)Some feedback about this Gas Container from our Clients:

5)Our customer testing the Air tightness for the gas tank container by themselves

6) Optional parts for the tanker contaier:

Volume: 20 cube meters to 45 cube meters for this Cryogenic Tank Container;Material: Carbon steel/aluminum/stainless steel material for this Cryogenic Tank Container;Medidum:LPG/LNG/LIN/LAR/LOX/LCO2,Liquid Ammonia,etc., Liquid Gas for this Cryogenic Tank Container;.

7) Brief Introduction To Our Factory:

Henan Jushixin Transportation Equipment , a special vehicle manufacturing corporation with the professional experience more than 30 years, certified by the Chinese government manufacture,Majored in Tank Containers, special vehicle manufacturing, our products are mainly exported to Philippine, Ethiopia, Thailand, Myanmar, Vietnam,Congo, Kenya, Tanzania, etc...More than 20 countries.

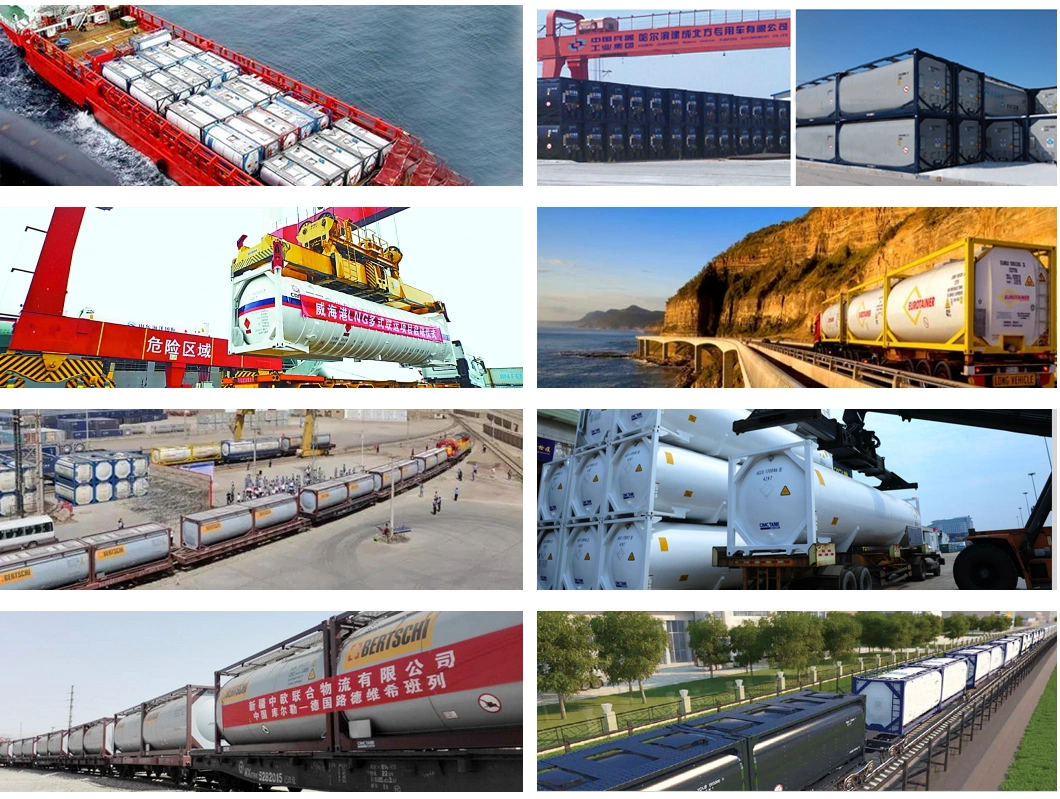

8) Some photos of the delivery about this Cryogenic ISO Tank Container:

9) Fiexible Service We Promised For Each Item From Our Factory:

>>>Offering the one-stop full lifecycle services for this Cryogenic Tank Container;;>>>Our vehicle users will receive 24-hour uninterruptible "Entire Journey" service for this Cryogenic Tank Container;;

>>>CCC&ISO Agreement, 1 Year Guarantee Term, Main-beam Lifetime Promise for this Cryogenic Tank Container;;>>> Small Order Can Be Accepted;>>>Any Color & Logo Available;>>>The Product Dimension + Specifications Can Be Designed As Your Needs.

10) Buying Guides for this LNG LIN Gas ISO Tank Container

**You please send us your enquiry for this Gas Container;**We shall reply you with the quotation of this Gas Container within 12 hours;**We negotiate on the configuration of this Gas Container that you need;**Confirmation of the tech data → sign contract (P/I) → 30% deposit (or L/C issuing)→ production for this Gas Container;**Manufacturing process updated news → completing production for this Gas Container;**Balance payment → ex works → shipment → custom clearance → A/S service for 1 year for this Gas Container.

Contact information for this gas container

Maggie SuenOffice.:+86-371-55628659 Mobile:+86-13838278359Web:hnjsx-trailer.en.made-in-china.com

Send to us