Cryogenic Storage Tank for Cryogenic Liquid Oxygen, Liquid Nitrogen, Liquid Argon, Liquid CO2

Overview Company ProfileGreenfir is a professional natural gas processing & liquefaction plant, air separation unit, hea

Basic Info

| Model NO. | LST |

| Storage Medium | Lox Lin Lar LNG Lco2 |

| Pressure Level | Medium Pressure (1.6MPa≤p<10.0MPa) |

| Condition | New |

| Transport Package | Seaworthy Packing |

| Specification | as reqyired |

| Trademark | Greenfir |

| Origin | China |

| HS Code | 7311009000 |

| Production Capacity | 1000 Sets/ Year |

Product Description

Company ProfileGreenfir is a professional natural gas processing & liquefaction plant, air separation unit, heat exchanger, reciprocating piston compressor, cryogenic cold box, fractionating column manufacturer and solutions provider with ISO 9001: 2015, ISO 14001: 2015, ISO 45001: 2018 and ASME U certified.We offer skid-mounted solutions optimized for each specific project, covering the following applications: Air Separation Plant, LNG Plant, Gas Purification & Liquefaction Unit, CNG/ LNG/ L-CNG Filling Station, Flare Gas Recovery Unit and Hydrogen Purification Unit, etc. We can deliver skid-mounted solutions customized to meet client's challenges and requirements (including adverse weather conditions, transportation and plot area limitations, etc).

We treat all the cryogenic solutions with serious attitudes and professional experience. Combined with our knowledge and experience, Greenfir provides each client with a technology-leading solution you can count on and bring a wider range of options and more profits.Product Description

| No. | Description | Medium | Remark |

| 1 | 5 m3 @ 0.8MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | |

| 2 | 10 m3 @ 0.8MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 3 | 15 m3 @ 0.8MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 4 | 20 m3 @ 0.8MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 5 | 30 m3 @ 0.8MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 6 | 50 m3 @ 0.8MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 7 | 100 m3 @ 0.8MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 8 | 150 m3 @ 0.8MPa, vertical | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 9 | 200 m3 @ 0.8MPa, vertical | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 10 | 5 m3 @ 1.6MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | |

| 11 | 10 m3 @ 1.6MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 12 | 15 m3 @ 1.6MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 13 | 20 m3 @ 1.6MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 14 | 30 m3 @ 1.6MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 15 | 50 m3 @ 1.6MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 16 | 100 m3 @ 1.6MPa, vertical/ horizontal | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 17 | 150 m3 @ 1.6MPa, vertical | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

| 18 | 200 m3 @ 1.6MPa, vertical | LOX, LIN, LAR, LCO2, LNG | strain-hardening |

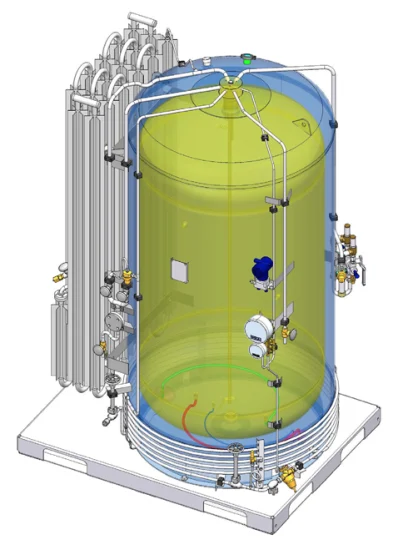

Cryogenic tanks have three basic components:

Inner Tank

Inner tank and pipes made of stainless steel to ensure high quality cleaning and with suitable strength properties when exposed to cryogenic temperatures.

Outer Vessel (Jacket)

An outer container made of carbon steel maintains the insulation and vacuum around the inner tank under normal operating conditions. Typically, the outer container is not exposed to cryogenic temperatures.

Insulation

The space between the inner tank and the outer container is filled with perlite, which has the ability to maintain cryogenic temperature, and is subjected to high vacuum treatment. The vacuum and insulating material help reduce heat transfer, thereby reducing boiling of liquid oxygen, liquid nitrogen, or liquid argon stored in the container.

Send to us