Factory Manufacturer 210L 1.37MPa Mobile Dewar Flask Liquid Nitrogen Cryogenic Gas Container for Oxygen/ Argon /Nirogen

Basic Info

| Model NO. | 210L |

| Double-Acting Cylinder Type | Double Rod Cylinder |

| Special Cylinder Type | Number of Cylinders |

| Combination Cylinder Type | Gas-Liquid Pressurized Cylinder |

| Product Name | Liquid Nitrogen Dewar Flask |

| Production Standard | DOT Standard, GB |

| Working Pressure | 1.37MPa |

| Effective Capacity | 189(L) |

| Dimension(D*H) | 508*1719mm |

| Height | 1719mm |

| Weight | 124kg |

| Marerial | Stainless Steel |

| Packing | Carton Box and Pallet |

| Application | Liquefied Gas |

| Transport Package | Carton Box and Pallet |

| Specification | 210L |

| Trademark | FORTERRA |

| Origin | China |

| HS Code | 731100900 |

| Production Capacity | 1000pieces/Year |

Product Description

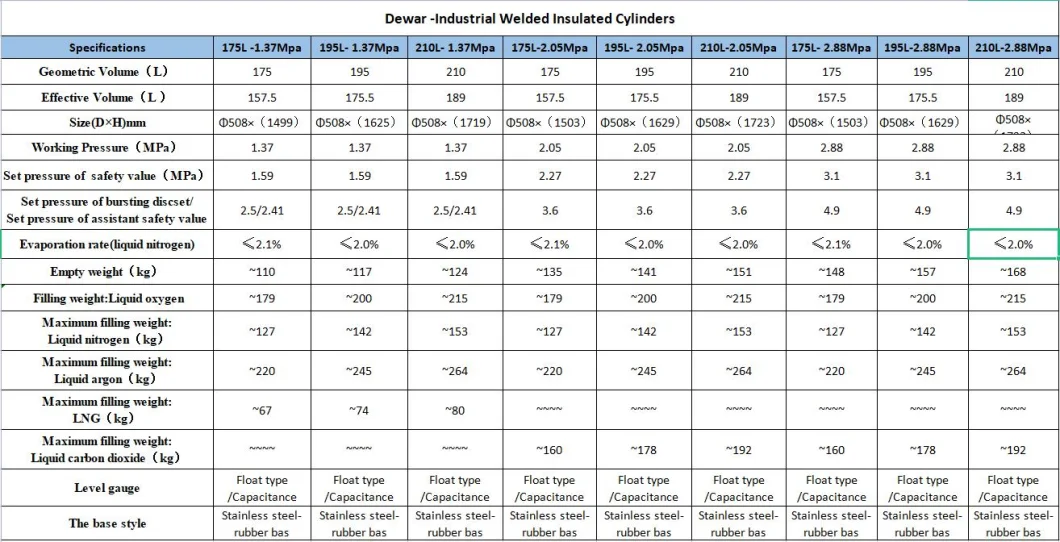

210L-1.37Mpa Capacity Dewar Storage Tank Cryogenic Liquid Dewar Flask For Liquid Oxygen/ NitrogenA cryogenic storage dewar (named after James Dewar) is a specialised type of vacuum flask used for storing cryogens (such as liquid nitrogen or liquid helium), whose boiling points are much lower than room temperature. Precautions are taken in the design of dewars to safely manage the gas which is released as the liquid slowly boils. The simplest dewars allow the gas to escape either through an open top or past a loose-fitting stopper to prevent the risk of explosion. More sophisticated dewars trap the gas above the liquid, and hold it at high pressure. This increases the boiling point of the liquid, allowing it to be stored for extended periods. Self-pressurising designs use the gas pressure in the top of the dewar to force the liquid upward through a pipe leading to the neck.| Product Name | Cryogenic Liquid Dewar Flask |

| Specification | 210L |

| Norminal Working Pressure | 1.37MPa |

| Opening Pressure of Safety Valve | 1.59MPa |

| Dimension(D*H) | 508*1719mm |

| Height | 1719mm |

| Weight | 124kg |

| Material | Stainless Steel |

| Standard | DOT, GB |

| Useage | Liquefied Gas |

| Packing | Carton Box |

Introduction-The face-to-face surfaces of the two walls of a dewar flask are silver plated or polished to reduce heat radiation.-The upper part or the neck of the inner wall is made of non-conductive materials to reduce heat transfer through solid materials.-The dewar bottle is widely used in liquefied gas production, storage, and transport.-It also a vacuum-insulated container commonly found in scientific research, medical health care and oil drilling.

Forterra Gas is a leading industrial gases and cylinders supplier in Shandong province, China. We supply a wide portfolio of Industrial gases, gas & safety equipment, solutions & services for gas applications across most industries, including Argon Gas, Oxygen Gas, Acetylene Gas, Helium Gas, Hydrogen Gas, Nitrogen Gas,Carbon Dioxide,Propane, Mixed Gas etc.

Our Pressure Vessel factory is one of the largest manufacturer of seamless high pressure cylinders. The company's advanced and sophisticated production process, state of the art equipment and stringent quality routines secure strong and safe cylinders with a long life time.

Forterra is trusted for its high standards and commitment to an excellent and stable quality by many industrial gas companies, as evidenced by exporting high pressure cylinders to more than 75 countries. We manufactures seamless high pressure cylinder with outside diameter ranging from 100 to 325mm and with a maximum working pressure of 300bar.

Forterra Gas is also a designer, manufacturer, supplier and installer of industrial gases production systems, including air separation plants, oxygen plants, acetylene plants, vaporizers, cryogenic liquid pumps, cryogenic liquid storage tanks etc, including associated engineering, construction, installation, training, start-up and maintenance services.

Q1: Are you manufacturer or trade company?A1: We are a Chinese manufacturer, and have been specializing in manufacturing gas cylinders for more than 10 years. Our company brand is "FA".

Q2: What is your daily production capacity?

A2: Our production capacity everyday is 800~1000 units.

Q3: What is your delivery time?

A3: Usually our delivery time is 25-45 days against the advance payment. Mainly it depends on when we get the production materials.

Q4: What certificates do you have?

A4: We have ISO9001 and IATF16949 for management system, and ISO9809, ISO11439 and ECE R110 for production approval.

Q5: Do you accept OEM production?

A5: Of course, we have served several famous motor OEMs, such as TOYOTA(Thailand)-Thailand, IKCO-Iran, GAZ-Russia, DF-China, and FOTON-China, etc. We would like to serve more customers with our superior quality.

Q6: Can you provide samples to us?

A6: Yes, we can provide 1-2 samples for your testing freely, but you need to undertake the logistic cost firstly.

Q7: Can you customize the products?

A7: Yes, we can provide you with various customized products. For example, your company brand/logo, different accessories and your favorite colors.