Lp LPG Gas Storage Tanks Price for Sale in Zimbabwe

Basic Info

| Model NO. | CIMC-LPGTANK |

| Condition | New |

| Capacity | 0.5~1000 M3 or Customized |

| Payload | 0.25~500 Tons or Customized |

| Working Pressure | Less Than 1.61MPa/1.724 MPa or Customized |

| Design Pressure | 1.61 MPa/1.724 MPa or Customized |

| Mawp | 1.77 MPa/1.724 MPa or Customized |

| Working Temperature | -20~50 Degrees or Customized |

| Design Temperature | -20/50 Degrees or Customized |

| Corrosion Allowance | 1.0mm or Customized |

| Hydrotest Pressure | 2.22MPa/2.25MPa or Customized |

| Shell Design Thickness | Customized |

| Head Design Thickness | Customized |

| Design Standard | ASME/GB |

| Transport Package | Normal |

| Specification | Customized |

| Trademark | CIMC HONTO |

| Origin | China |

| HS Code | 73110090 |

| Production Capacity | 2000/Year |

Product Description

LPG Storage Tank

HONGTU has the design & fabrication capacity of LPG stationary storage tanks including above-ground tanks, underground tanks and mounded tanks etc. All kinds of tanks could be customized according to the customers' requirements.

Design Standard:

ASME BPVC VIII-1 2017 ; NB/T47042-2014 GB/T150-2011 TSG 21-2016

Main Material:

SA-516, SA-612,Q370R etc.

Above-ground LPG Storage Tank

| I.Chinese Standard | ||||

| Capacity | Diameter x Height x Length | Tank Weight | Payload | Thickness |

| 10m3 | φ1600×2370×5300mm | 3400kg | 4035kg | Shell 8.53mm/Head 8.51mm |

| 20m3 | φ2200×2970×5680mm | 5150kg | 8070kg | Shell 11.35mm/Head 11.33mm |

| 32m3 | φ2200×2970×8850mm | 7200kg | 12920kg | |

| 40m3 | φ2470×3240×8843mm | 8780kg | 16410kg | Shell 12.62mm/Head 12.59mm |

| 50m3 | φ2470×3240×10903mm | 10420kg | 20180kg | |

| 63m3 | φ2470×3240×13623mm | 12600kg | 25420kg | |

| 80m3 | φ3100×3800×11170mm | 16700kg | 32280kg | Shell 15.58mm/Head 15.87mm |

| 100m3 | φ3100×3800×13850mm | 20000kg | 40350kg | |

| 120m3 | φ3400×4104×13840mm | 24500kg | 48400kg | Shell 17.35mm/Head 17.31mm |

| 150m3 | φ3400×4104×17140mm | 29800kg | 60500kg | |

| 200m3 | φ3800×4560×18324mm | 40100kg | 80700kg | Shell 19.27mm/Head 19.22mm |

| Main Material | Q345R | Design Pressure | 1.61Mpa |

| Hydraulic Test Pressure | 2.22Mpa | Working Pressure | ≤1.61Mpa |

| Corrosion Allowance | 1mm | Design Temperature | -20~50ºC |

| Life Expectancy | 20years | Working Temperature | -20~50ºC |

| II.ASME Standard | ||||

| Capacity | Diameter x Height x Length | Tank Weight | Payload | Thickness |

| 10m3 | φ1600×2440×5308mm | 3850kg | 4630kg | Shell 11.09mm/Head 11.02mm |

| 20m3 | φ2200×3050×5690mm | 6920kg | 9260kg | Shell 14.86mm/Head 14.78mm |

| 32m3 | φ2200×3050×8860mm | 9750kg | 14820kg | |

| 40m3 | φ2470×3320×8851mm | 11930kg | 18530kg | Shell 16.56mm/Head 16.47mm |

| 50m3 | φ2470×3320×10911mm | 15420kg | 25470kg | |

| 60m3 | φ2470×3320×13001mm | 16600kg | 27790kg | |

| 80m3 | φ3100×3960×11178mm | 22820kg | 37060kg | Shell 20.53mm/Head 20.41mm |

| 100m3 | φ3100×3960×13858mm | 27430kg | 46320kg | |

| 120m3 | φ3200×3542×16100mm | 26100kg | 51000kg | Shell 20.14mm/Head 10.07mm |

| 150m3 | φ3300×4210×18158mm | 39930kg | 69480kg | Shell 21.79mm/Head 21.66mm |

| Main Material | SA-516 Gr.70 | Design Pressure | 1.724Mpa |

| Hydraulic Test Pressure | 2.25Mpa | Working Pressure | ≤1.724Mpa |

| Corrosion Allowance | 1mm | Design Temperature | 50ºC |

| Specific Gravity | [email protected]ºC | Working Temperature | -20~50ºC |

| Chinese GB Standard | |||||||

| Water Capacity | Inner Diameter | Overall Length | Height | Weight | Payload(90% Filling Ratio) | Thickness | |

| Shell | Heads | ||||||

| 7m³ | 1200mm | 6560mm | 2430mm | 3100kg | 2820kg | 7.5mm | 6.64mm |

| 10m³ | 1600mm | 5300mm | 2870mm | 3800kg | 4035kg | 8.53mm | 8.51mm |

| 20m³ | 2000mm | 6800mm | 3290mm | 5900kg | 8070kg | 10.41mm | 10.39mm |

| 25m³ | 2200mm | 7000mm | 3484mm | 6300kg | 10090kg | 11.36mm | 11.33mm |

| 50m³ | 2470mm | 10903mm | 3756mm | 11220kg | 20180kg | 12.62mm | 12.59mm |

| Main Material | Q345R | Design Pressure | 1.61MPa |

| Hydraulic Test Pressure | 2.22MPa | Working Pressure | ≤1.61MPa |

| Corrosion Allowance | 1.0mm | Design Temperature | -20/50ºC |

| Life Expectancy | 20 years | Working Temperature | -20/50ºC |

| ASME Standard | |||||||||

| Water Capacity | Inner Diameter | Overall Length | Height | Weight | Payload (90% Filling Ratio) | Material | Design Pressure | Thickness | |

| Shell | Heads | ||||||||

| 22m³ | 2000mm | 7420mm | 2774mm | 6200kg | 8876kg | Q345R | 1.61MPa | 11.56mm | 10.47mm |

| 98.5m³ | 3500mm | 11588mm | 3548mm | 25100kg | 47073kg | SA-516 GR.70 | 1.724MPa | 23.05mm | 13.21mm |

| 124m³ | 3450mm | 14410mm | 5140mm | 26500kg | 60890kg | 1.38MPa | 18.98mm | 10.28mm | |

Jingmen Hongtu Special Aircraft Manufacturing (hereinafter called HONGTU, and branded as HONTO) has made prominent contributions to the development of China's aviation industry since established in 1971 as the AVIC Corp II factory No. 322. Now, Hongtu as a key enterprise under China International Marine Containers (Group) Ltd. (CIMC) (ranked the 68th in China's Top 500 businesses), is engaged in R & D of normal temperature storage & transportation equipment, cryogenic storage & transportation equipment, EPC services, chemical equipment and other types of energy chemical storage & transportation equipment. The Company has more than 1,300 employees, including approx. 200 R&D professionals, and has workshop area totaling 130,000 m2.

In the 1980s, HONGTU entered into the industry of hazardous chemicals storage & transportation equipment manufacturing based on the advantages of aviation technology, providing customers with individualized and integrated solutions in the fields of hazardous chemicals'storage & transportation, gasification in cities/towns and vehicle/vessel's oil-to-gas transformation.

The Company always leads the development of the industry. The production and sales of "HONTO" Brand LPG tanker has been ranking No.1 in China in the past 36 years. The domestic market share of HONGTO reaches over 60% all along. HONGTU has been engaged in the manufacturing of energy and chemical storage & transportation equipment for over 3 decades and is also China's only LPG full-industrial chain equipment manufacturer and solution provider.

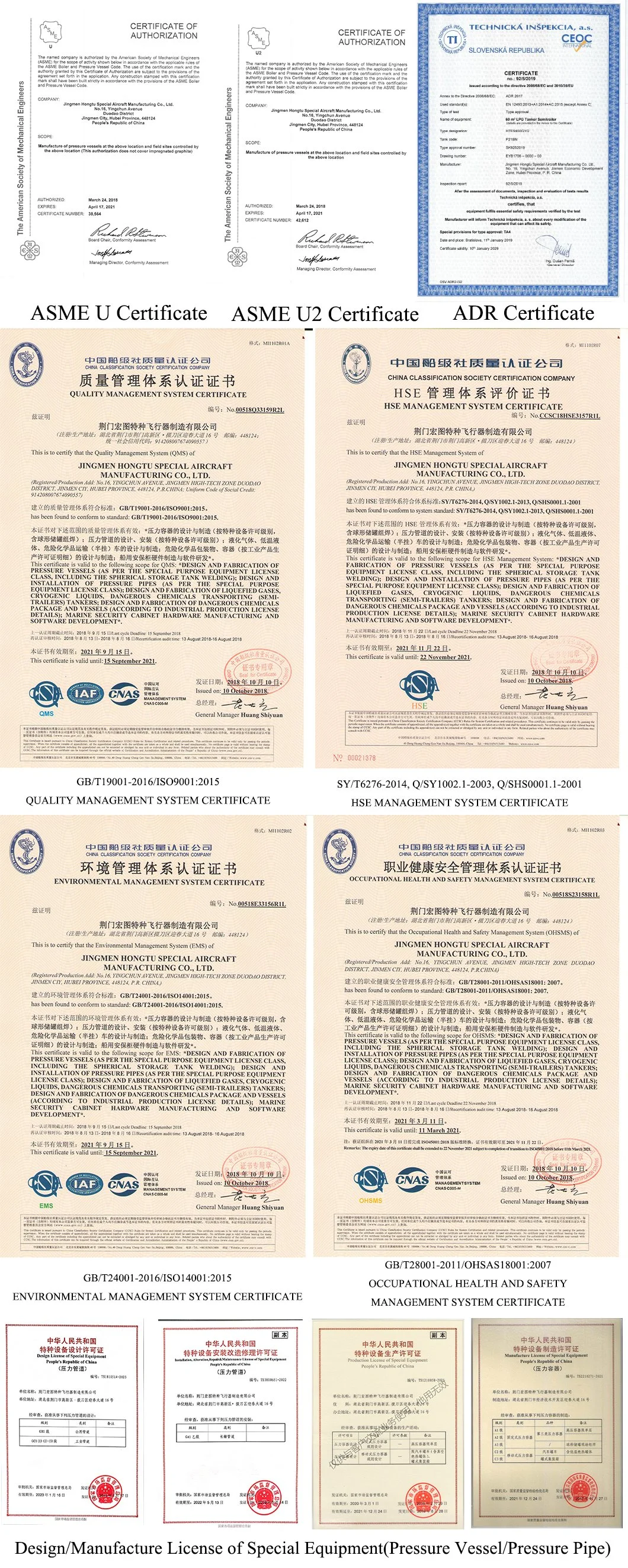

The Company has ASME "U" and "U2" Stamps Qualification and all Chinese National Permits for design, manufacture and installation of various pressure vessels, spherical tanks, urban gas pipeline projects and marine fuel tanks, and has developed and drafted a number of national standards on pressurized and non-pressurized products of China.

The Company provides global customers and partners with safe, efficient and value-added energy and chemical storage &

transportation equipment under the concept of providing service in the full product life cycle and creating values for customers, through the three-in-one marketing mode of brand communication, product sale and lifelong service, and is committed to become a leading competitive supplier with in the field of global energy chemical industry.

"HONTO" brand LPG storage and transportation equipment has been distributed to more than 40 countries & regions in North America, South America, Southeast Asia, South Asia, Middle East and Africa, etc.