Cryogenic Liquid Oxygen Dewar Cylinder Price

Main Performance features of dewar gas cylinder: Q1: How to ensure your cylinders quality? A: we have been in this field

Basic Info

| Material | Stainless Steel |

| Usage | Print, Automation and Control |

| Structure | Gas - Liquid Damping Cylinder |

| Power | Hydraulic |

| Standard | Standard |

| Pressure Direction | Single-acting Cylinder |

| Double-Acting Cylinder Type | Double Rod Cylinder |

| Special Cylinder Type | Number of Cylinders |

| Combination Cylinder Type | Pressurized Cylinder |

| Cylinder Material | 06cr19ni10/304 |

| Transport Package | Export Standard Packing |

| Specification | 500L |

| Trademark | DSW |

| Origin | China |

| HS Code | 731100 |

| Production Capacity | 500 Per Day |

Product Description

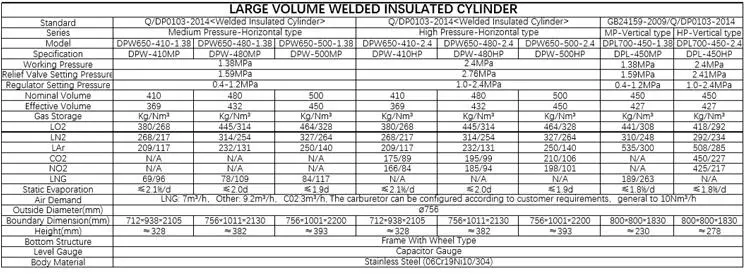

Main Performance features of dewar gas cylinder:| Medium pressure cryogenic liquid container gas dewar cylinder | ||

| Model | DPW-499 | |

| size mm | 2113×760×995mm | |

| working pressure(MPa) | 1.59 | |

| Relief valve take-off pressure(MPa) | 1.89 | |

| Bursting pressure of the bursting disc(MPa) | 2.41(2.86*) | |

| Geometric volume (L) | 499 | |

| Effective volume(L) | 460 | |

| Evaporation rate (liquid nitrogen) | 1.70% | |

| Empty cylinder weight(kg) | 345 | |

| Filling Medium | O2(kg) | 478 |

| N2(kg) | 334 | |

| Ar(kg) | 585 | |

| LNG(kg) | 196 | |

| High pressure product cryogenic liquid container gas dewar cylinder | ||

| Model | DPW-499H | |

| size mm | 2113×760×995 | |

| working pressure(MPa) | 2.5 | |

| Relief valve take-off pressure(MPa) | 2.86 | |

| Bursting pressure of the bursting disc(MPa) | 3.62(4.14*) | |

| Geometric volume (L) | 499 | |

| Effective volume(L) | 460 | |

| Evaporation rate (liquid nitrogen) | 1.70% | |

| Empty cylinder weight(kg) | 405 | |

| Filling Medium | O2(kg) | 478 |

| N2(kg) | 334 | |

| Ar(kg) | 585 | |

| LNG(kg) | 460 | |

A: we have been in this field for more than 20 years. Our products have been sold almost all over the world. We allow 3rd party inspections before shipment ( on buyer's account) And we can supply certificate of quality accordingly.

Plus we have six machinery equipments to test material and cylinder:

1. spectrum analyzer to detect chemical analysis;

2. mechanical function to make tension test and bending test;

3. X-ray silent detection to inspect circumferential weld;

4. Hydraulic bursting test;

5. Hydraulic testing;

6. Air tightness test.

Q2: About the brand name of the products?

A: In general, We use our own brand "DSW", if you have requested, Both OEM and ODM arealso available.

Q3:Can you provide a sample?

In our acceptable range, we can offer one free sample for you if you pay for the freight. We will return the freight if you make an order in future.

Q4: How about your delivery time?

In general, it will take 35-60 days after receiving deposit. The specific delivery time depends on the items and quantity of your order.

Q5: What is your MOQ?

Small quantity negotiable, one or more containers would be appreciated.

Send to us